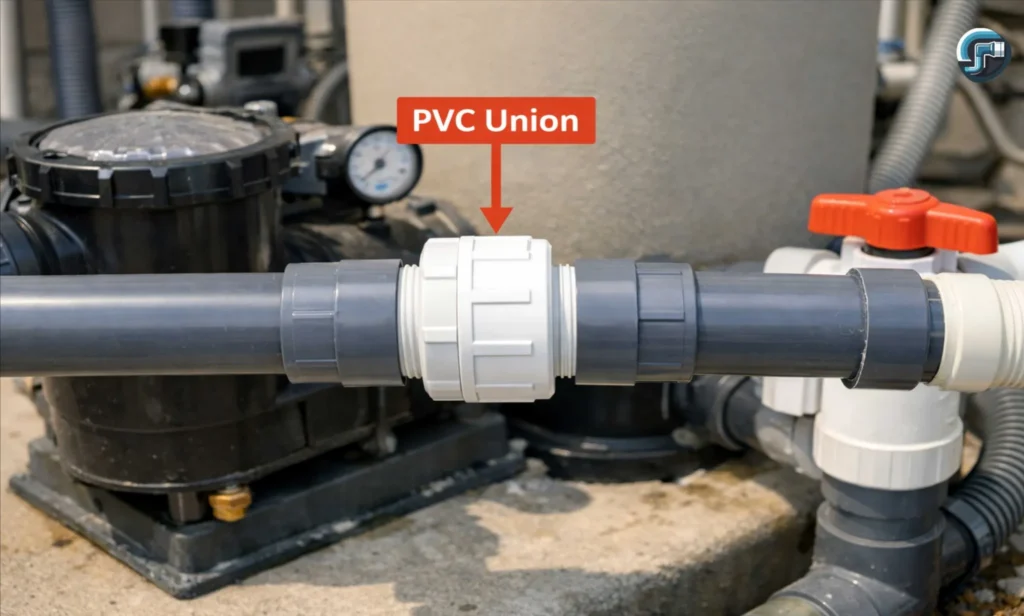

PVC Union Fitting

PVC Union has the ability to disconnect and reconnect the pipes without cutting, it has a major advantage in plumbing and piping systems. Even though it looks quite simple, it has a major role in connection of pipes. Its three piece fitting is designed to join two sections of pipe and allow the connection to be disassembled when required. Disassembling of pipes is very important where regular maintenance, inspection or future modification is required. Unlike standard PVC couplings that create a permanent solvent-welded joint, a PVC union can be separated without damaging the pipe, making it a practical and efficient solution for serviceable piping installations.

Why and When to Use PVC Unions?

The best benefit in the use of pvc unions is serviceability. They introduce a deliberate weak spot in a pipe system which can easily be accessed without damaging the pipe. The serviceability is essential in numerous domestic, commercial and industrial uses.

Practical Applications

- Pool and Spa Systems: Unions are typically used for plumbing pumps, heaters, filters, and chlorinators. This allows for ease of winterising or replacement of equipment without the necessity for re-plumbing the entire system. A 2 in pvc union is very common for this type of application.

- Irrigation and Sprinkler Systems: Putting unions on both sides of valves or backflow preventers makes maintenance and repairs one step easier. In the event a valve breaks, you can simply unscrew the unions and replace it.

- Sump Pump Installations: A PVC union in the sump discharge line allows the pump to be removed for maintenance or replacement without the pipe having to be cut. It is a significant component in basement waterproofing systems.

- Aquaculture and Aquariums: Large aquarium systems use unions for the fittings of filters, protein skimmers, and UV sterilizers so facilitating easy cleaning or upgrading of parts.

- Water Treatment Systems: Connecting water softeners, carbon filters, or reverse osmosis systems by unions facilitates servicing of the units or replacement of the media.

- Industrial Piping: In chemical processing or manufacturing plant applications, unions allow sections of the piping to be removed for inspection, cleaning, or rearranging.

The general rule is to put in a PVC union fitting wherever you may possibly have to disassemble the pipe in the future. It’s a cheap investment and one you’ll appreciate down the road for the money saved in time and frustration.

PVC Union Sizes and Types Explained

PVC unions can be bought in many different sizes in a way of accommodating the standard PVC pipe diameters. Its size ranges from ½ inch to 12 inches. The union is the same size as the nominal pipe size it is designed for. When you consider a size like 2 pvc union, you are referring to a fitting designed for use by connecting two 2 inch nominal size PVC pipes.

There are different sizes of PVC Unions available which can be used according to need. The size of PVC Union is the same as PVC Pipe. For example you’re going to connect two 3 inch nominal size PVC pipes then you need a 3 inch PVC Union.

Types of Connections

Although the most general-purpose PVC union is the solvent-welded one having end-to-end sockets (Socket x Socket), others are also made for designated applications:

- Socket x Threaded: It consists of one end having a solvent weld socket and the other a male or female pipe threads (MPT or FPT). It is useful for fitting a PVC pipe directly onto a threaded valve or pump outlet.

- Threaded x Threaded: Both ends are threaded and have no need for solvent welding. They are not very popular for the standard PVC pipe but are a glueingSpeciality for certain uses.

- Speciality Unions: Some unions are designated for use in applications such as high pressure or for different materials such as CPVC.

PVC Union Sizes

PVC unions can be bought in many different sizes in a way of accommodating the standard PVC pipe diameters. Its size ranges from ½ inch to 12 inches. The union is the same size as the nominal pipe size it is designed for. When you consider a size like 2 inch PVC union, you are referring to a fitting designed for use by connecting two 2 inch nominal size PVC pipes.

There are different sizes of PVC Unions available which can be used according to need. The size of PVC Union is the same as PVC Pipe. For example you’re going to connect two 3 inch nominal size PVC pipes then you need a 3 inch PVC Union.

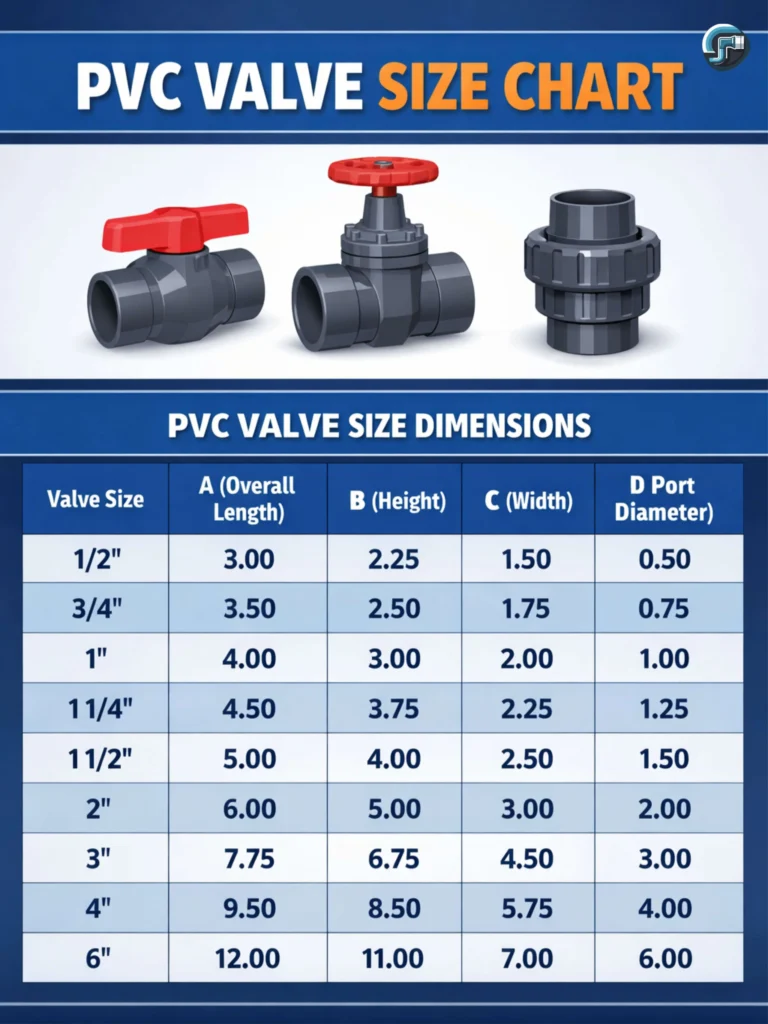

PVC Union Size Chart

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Connection Types Available |

| 1/2 inch PVC Union | 0.840 in (21.34 mm) | Slip, Threaded |

| 3/4 inch PVC Union | 1.050 in (26.67 mm) | Slip, Threaded |

| 1 inch PVC Union | 1.315 in (33.40 mm) | Slip, Threaded |

| 1 1/4 inch PVC Union | 1.660 in (42.16 mm) | Slip, Threaded |

| 1 1/2 inch PVC Union | 1.900 in (48.26 mm) | Slip, Threaded |

| 2 inch | 2.375 in (60.33 mm) | Slip, Threaded |

| 2 1/2 inch | 2.875 in (73.03 mm) | Slip only (commonly) |

| 3 inch | 3.500 in (88.90 mm) | Slip, Threaded |

| 4 inch | 4.500 in (114.30 mm) | Slip, Threaded |

| 5 inch | 5.563 in (141.30 mm) | Slip, Threaded |

| 6 inch | 6.625 in (168.28 mm) | Slip, Threaded |

| 8 inch | 8.625 in (219.08 mm) | Slip, Threaded |

| 10 inch | 10.750 in (273.05 mm) | Slip, Threaded |

| 12 inch | 12.750 in (323.85 mm) | Slip, Threaded |

Types of Connections

Although the most general-purpose PVC union is the solvent-welded one having end-to-end sockets (Socket x Socket), others are also made for designated applications:

- Socket x Threaded: It consists of one end having a solvent weld socket and the other a male or female pipe threads (MPT or FPT). It is useful for fitting a PVC pipe directly onto a threaded valve or pump outlet.

- Threaded x Threaded: Both ends are threaded and have no need for solvent welding. They are not very popular for the standard PVC pipe but are a gluing Speciality for certain uses.

- Speciality Unions: Some unions are designated for use in applications such as high pressure or for different materials such as CPVC.

How to Install a PVC Union Fitting?

Installing a PVC union is a straightforward process that follows the basic principles of solvent welding PVC pipe. Precision and proper technique are key to ensuring a durable, leak-free connection.

Tools and Materials Needed

- PVC Pipe Cutter or Saw

- Deburring Tool or Utility Knife

- PVC Primer (clear or purple)

- PVC Cement (appropriate for your pipe schedule and conditions)

- Tape Measure

Step-by-Step Installation Guide

Step 1: Disassemble and Prepare the Union

First, unscrew the union nut and separate the three pieces. This prevents you from accidentally glueing pressurising the union together. Set the nut and one of the ends aside.

Step 2: Measure and Cut Your Pipe

Measure the distance for your pipe run, accounting for the socket depth of the union ends. A PVC union will add length to your pipe run, so ensure your measurements are precise. Cut your PVC pipes to the required lengths using a PVC cutter or a fine-toothed saw. Make sure your cuts are straight and square.

Step 3: Deburr and Clean the Pipe Ends

Use a deburring tool, a file, or a utility knife to remove any burrs from the inside and outside of the cut pipe ends. Burrs can scrape away cement and create leak paths. After deburring, wipe the pipe ends and the inside of the union sockets with a clean, dry rag to remove any dirt, grease, or moisture.

Step 4: Dry Fit the Components

Before applying any primer or cement, perform a dry fit. Slide the union sockets onto the pipe ends to ensure they fit correctly. The pipe should go about halfway to two-thirds of the way into the socket. This is also a good time to slide the union nut onto one of the pipes, ensuring it is oriented correctly to thread onto the other union end later. Many plumbers forget this step and end up trapping the nut.

Step 5: Apply Primer

Working in a well-ventilated area, apply a liberal coat of PVC primer to the outside of the pipe end and the inside of the union socket. The primer cleans the PVC and begins to soften the plastic, which is essential for a strong weld. The primer should be applied to an area slightly larger than the socket depth.

Step 6: Apply Cement and Join the Pieces

Immediately after applying primer (while it’s still wet), apply a thin, even layer of PVC cement to the primed areas on both the pipe and the socket. Avoid using too much cement, as excess can puddle inside the pipe and restrict flow.

Push the pipe into the socket with a quarter-turn twisting motion. This helps spread the cement evenly and ensures a good bond. Hold the pipe and fitting together firmly for about 30 seconds, as the chemical reaction can sometimes push the pipe back out of the socket.

Step 7: Repeat for the Other Side

Repeat the priming and cementing process for the other pipe and the remaining union socket. Remember to make sure the union nut is already on one of the pipes before you glue the second end.

Step 8: Assemble the Union and Cure

Once both sockets are solvent-welded to the pipes, you can bring the two halves of the union together. Ensure the O-ring is properly seated in its groove. Align the threads and hand-tighten the union nut. For most applications, hand-tightening is sufficient to create a seal. Over-tightening with a wrench can crack the nut or damage the O-ring.

Allow the solvent welds to cure for the manufacturer-recommended time before pressurising the system. Cure times vary based on pipe size, temperature, and humidity.

Common Mistakes to Avoid

- Forgetting the Union Nut: A classic mistake is solvent welding both ends of the union to the pipes without first sliding the union nut onto one of them. This makes the union useless, and you’ll have to cut it out.

- Over-Tightening: Using a large wrench to tighten the union nut can cause stress fractures in the plastic. Hand-tight plus a quarter-turn with a strap wrench is usually the maximum force needed.

- Misaligning Threads: Cross-threading the nut can permanently damage the union. Always start the threads by hand to ensure they are properly aligned.

- Skipping Primer: Primer is not just a cleaner; it’s a critical chemical that softens the PVC. Skipping this step results in a weak joint that is likely to fail under pressure.

Not Deburring: Sharp edges on a cut pipe can scrape away cement as you push it into the socket, creating a channel for leaks.

Maintaining and Troubleshooting PVC Unions

The best advantage of a PVC union is the serviceability. In the long term, you may have to access the union for repair or find the union having a slow leak.

Opening a Union

To gain access to a union, unscrew the very large center nut. If it does not turn by hand, use a strap wrench or very large channel-lock pliers. Exercise care and carefully apply force not to crack the nut. Once loose you should easily be able to pull the two pipe sections apart.

Dealing with Leaks

A PVC union leak is almost always the consequence of one of the following three issues:

- The Nut Is Loose: The system vibration (in a pump system in particular) can loosen a nut slightly over time. Your first try should be a hand-tight.

- The O-Ring is Cracked or Dislodged: In the event you cannot stop the leak by turning the nut tight, then the O-ring is the likely culprit. Remove the union and inspect the O-ring. It may be grimy, dry, cracked, or not properly seated in the groove. Attempt to clean the O-ring and groove and apply a water-fast or waterproof lubricating oil or grease and then properly reseat the O-ring. Replace it if it is broken. O-rings are inexpensive and easily obtained at a hardware store or pool supply store.

- The Union is Cracked: The union body or nut can be cracked by physical damage or by being overtightened. Once you find a crack, the entire union must be cut away and replaced. It is not possible to properly repair a cracked PVC union fitting.

Frequently Asked Questions

Conclusion

The union in PVC is a quintessential good design for plumbing. It provides a trouble-free and easy way of overcoming the common problem of having to disconnect and reconnect pipes. With unions fitted at strategic points—that is, near pumps, filters, and valves for a case in point—you are building a system not merely helpful for the task at hand but serviceable and repairable too.

From a small Union PVC 1/2 in an aquarium setup to a robust 2 1/2 PVC Union in a commercial irrigation system, this versatile fitting saves time, effort, and money. PVC Union could make your life easier in the future.