PVC Pipe Sizes

PVC Pipe Dimensions – Complete Guide to Dimensions, Types, and Applications

At JM Engineering our aim is to provide accurate and updated information. The PVC Pipe Size Chart is very impotent to calculate pipe weight pressure flow and temperature ratting. PVC Pipe dimensions are an indispensable tool in industries like plumbing to the electrical conduits and oil & gas RO plants and irrigation.

In this complete guide, we tried to equip you with all the knowledge concerning the sizes of PVC pipe in mm and inches, how PVC pipe sizing is done, and special cases, such as the introduction of Schedule 80 PVC pipe, smallest PVC pipe and the largest PVC pipe size available on the market.

Understanding PVC Pipe Sizing Basics

Before diving into the numbers, it helps to understand what you’re working with. PVC is a thermoplastic polymer widely used in construction because it’s strong, resistant to chemicals, and easy to install.

Definition and Composition

PVC stands for Polyvinyl Chloride. It’s created by polymerising vinyl chloride monomers. In its rigid form (UPVC pipe schedule 40 is a common variation), it is incredibly hard and durable. Unlike metal pipes, PVC doesn’t rust or corrode over time, which is a massive advantage for water transport systems.

Common Applications

You’ll find PVC everywhere.

Construction: Electricians use schedule 40 and schedule 80 conduit to protect electrical wiring.

Plumbing: It’s the standard for residential drain lines and vents.

Irrigation: Farmers and landscapers use schedule 40 PVC tubing for sprinkler systems.

Pros and Cons

Advantages:

- Corrosion Resistance: It doesn’t rot or rust.

- Cost-Effective: Generally cheaper than copper or steel.

- Flow Rate: The smooth interior surface reduces friction, allowing for better water flow.

Disadvantages:

- Temperature Sensitivity: Standard PVC can deform at high temperatures (usually above 140°F).

- UV Sensitivity: Prolonged exposure to sunlight can make untreated PVC brittle.

PVC Pipes Sizes Chart

PVC Pipe Schedule 40

| Nom. Pipe Size (in) | O.D | Average I.D | Min. Wall | Nominal Wt./Ft. | Maximum W.P. PSI |

| 1/8 | 0.405 | 0.249 | 0.068 | 0.051 | 810 |

| 1/4 | 0.540 | 0.344 | 0.088 | 0.086 | 780 |

| 3/8 | 0.675 | 0.473 | 0.091 | 0.115 | 620 |

| 1/2 | 0.840 | 0.602 | 0.109 | 0.170 | 600 |

| 3/4 | 1.050 | 0.804 | 0.113 | 0.226 | 480 |

| 1 | 1.315 | 1.029 | 0.133 | 0.333 | 450 |

| 1-1/4 | 1.660 | 1.360 | 0.140 | 0.450 | 370 |

| 1-1/2 | 1.900 | 1.590 | 0.145 | 0.537 | 330 |

| 2 | 2.375 | 2.047 | 0.154 | 0.720 | 280 |

| 2-1/2 | 2.875 | 20445 | 0.203 | 1.136 | 300 |

| 3 | 3.500 | 3.042 | 0.216 | 1.488 | 260 |

| 3-1/2 | 4.000 | 3.521 | 0.226 | 1.789 | 240 |

| 4 | 4.500 | 3.998 | 0.237 | 2.118 | 220 |

| 5 | 5.563 | 5.016 | 0.258 | 2.874 | 190 |

| 6 | 6.625 | 6.031 | 0.280 | 3.733 | 180 |

| 8 | 8.625 | 7.942 | 0.322 | 5.619 | 160 |

| 10 | 10.750 | 9.976 | 0.365 | 7.966 | 140 |

| 12 | 12.750 | 11.889 | 0.406 | 10.534 | 130 |

| 14 | 14.000 | 13.073 | 0.437 | 12.462 | 130 |

| 16 | 16.000 | 14.940 | 0.500 | 16.286 | 130 |

| 18 | 18.000 | 16.809 | 0.562 | 20.587 | 130 |

| 20 | 20.000 | 18.743 | 0.593 | 24.183 | 120 |

| 24 | 24.000 | 22.544 | 0.687 | 33.652 | 120 |

This chart lists the standard dimensions of PVC Schedule 40 pipes, including nominal size, outside diameter, inside diameter, and wall thickness. Nominal size is not the actual measurement—use outside diameter for fittings and inside diameter to estimate flow capacity.

PVC Pipe Schedule 80

| Nominal Pipe Size (in) | O.D | Average I.D | Min Wall | Nominal Wt./ft. | Maximum W.P. PSI* |

| 1/8 | 0.405 | 0.195 | 0.095 | 0.068 | 1230 |

| 1/4 | 0.540 | 0.282 | 0.119 | 0.115 | 1130 |

| 3/8 | 0.675 | 0.403 | 0.126 | 0.158 | 920 |

| 1/2 | 0.840 | 0.526 | 0.167 | 0.232 | 850 |

| 3/4 | 1.050 | 0.722 | 0.154 | 0.314 | 690 |

| 1 | 1.315 | 0.936 | 0.179 | 0.461 | 630 |

| 1-1/4 | 1.660 | 1.255 | 0.191 | 0.638 | 520 |

| 1-1/2 | 1.900 | 1.476 | 0.200 | 0.773 | 470 |

| 2 | 2.375 | 1.913 | 0.218 | 1.070 | 400 |

| 2-1/2 | 2.875 | 2.29 | 0.276 | 1.632 | 420 |

| 3 | 3.500 | 2.864 | 0.300 | 2.186 | 370 |

| 4 | 4.500 | 3.786 | 0.337 | 3.196 | 320 |

| 6 | 6.625 | 5.709 | 0.432 | 6.102 | 280 |

| 8 | 8.625 | 7.565 | 0.500 | 9.269 | 250 |

| 10 | 10.750 | 9.493 | 0.593 | 13.744 | 230 |

| 12 | 12.750 | 11.294 | 0.687 | 18.909 | 230 |

| 14 | 14.000 | 12.41 | 0.750 | 22.681 | 220 |

| 16 | 16.000 | 14.213 | 0.843 | 29.162 | 220 |

| 18 | 18.000 | 16.014 | 0.937 | 36.487 | 220 |

| 20 | 20.000 | 17.814 | 0.031 | 44.648 | 220 |

| 24 | 24.000 | 21.418 | 1.218 | 63.341 | 210 |

This chart shows the standard dimensions of PVC Schedule 80 pipes, including nominal size, outside diameter, inside diameter, and wall thickness. Schedule 80 pipes have thicker walls than Schedule 40, offering higher pressure strength; use outside diameter for fittings and inside diameter to calculate flow capacity.

Standard PVC Pipe Sizes Explained

One of the most confusing aspects of buying pipe is the sizing system. You might pick up a pipe labeled “1 inch,” measure it, and find the outside diameter is actually 1.315 inches. Why the discrepancy?

Nominal Pipe Size (NPS) vs. Outside Diameter (OD)

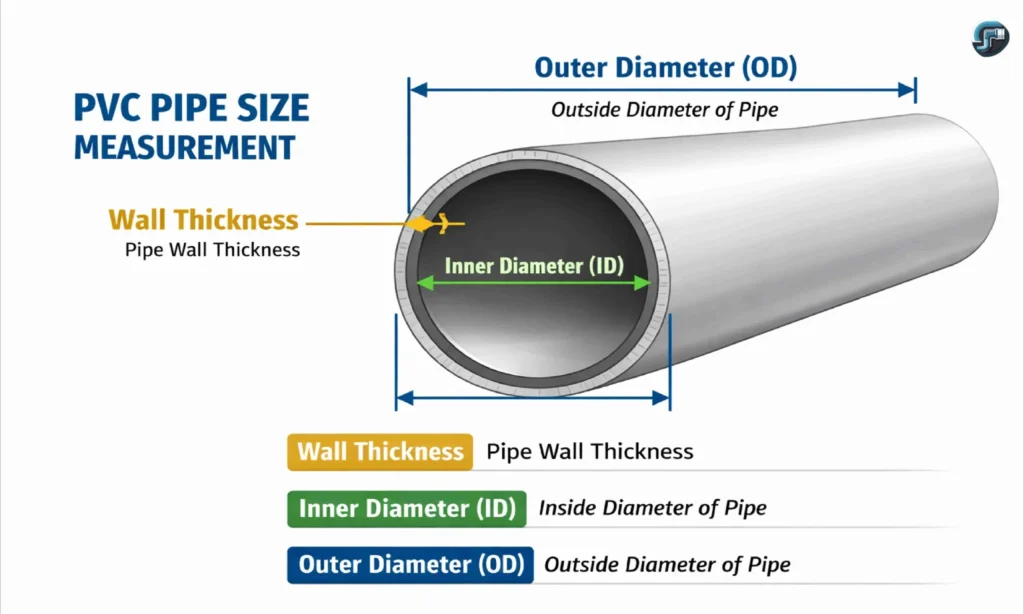

PVC pipe sizes use a standard known as Nominal Pipe Size (NPS). The “nominal” size refers to the approximate inside diameter (ID) of the pipe, not the outside. However, the exact ID changes based on the thickness of the pipe wall (the schedule).

The critical thing to remember is that the Outside Diameter (OD) is constant for a specific pipe size, regardless of the schedule. This ensures that fittings fit all schedules of the same pipe size. For example, a 1-inch Schedule 40 pipe and a 1-inch Schedule 80 pipe will both fit into a 1-inch coupling because their OD is the same.

Explanation of Schedule Numbers

The “schedule” refers to the wall thickness of the pipe.

- Schedule 40 PVC: This is the standard for most home repairs and irrigation. It has a thinner wall compared to Schedule 80.

- Schedule 80 PVC: This pipe has thicker walls, making it stronger and able to handle higher pressures. Because the walls are thicker and the OD stays the same, the PVC pipe ID size (inside diameter) is smaller than Schedule 40.

How to Measure the Size of PVC Pipe?

If you are repairing an existing system, you need to know the PVC pipe dimensions exactly.

Tools Needed

You don’t need fancy equipment. A simple tape measure or a set of calipers will work.

Method

- Check the Label: Look for the print on the side of the pipe. It will usually say something like “1 1/2 inch Schedule 40 PVC ASTM D1785.” This is the easiest way to identify it.

- Measure the OD: If the label is faded, measure the outside diameter across the widest part of the cut end.

- If it measures 0.840 inches, it’s a 1/2-inch pipe.

- If it measures 1.315 inches, it’s a 1-inch pipe.

- If it measures 2.375 inches, it’s a 2-inch pipe.

- Check the ID: If you need to distinguish between schedules, measure the ID size PVC. A smaller hole with the same OD means a higher schedule (thicker wall).

PVC Pipe: Schedule 40 vs. Schedule 80

When people are buying PVC pipe, they often assume that Schedule 80 PVC pipe is stronger than Schedule 40 PVC pipe – why?

Wall Thickness: Schedule 80 has thicker walls and is better at handling high pressures.

Schedule 80 pipes are usually gray, and Schedule 40 pipes are usually white.

Uses: Schedule 80 is more commonly used in factories and chemical plants. Schedule 40 is used for plumbing in homes and businesses.

For example:

- The inside diameter of a 2″ Schedule 40 pipe is approximately 2.067″.

- A 2″ Schedule 80 pipe has an inside diameter of approximately 1.939″, due to the wall thickness.

- There are two main standards for the sizes of PVC pipes;

- PVC Schedule 40 Pipe Sizes is the most common type of pipe used for plumbing, drainage and irrigation.

- Schedule 80 has thicker walls, can withstand higher pressure; it is used for installing jobs that are very strength-heavy and happen to be expected to be durable.

- For a certain nominal dimension, the two schedules have the same OD, but their wall thickness and ID are different.

PVC sizes in both inches and millimeters

- Most of the time, PVC pipes in the US are measured in inches, but in some other countries, they are measured in mm.

- A PVC pipe that is nominally 1 inch in diameter has an outside diameter of about 33.4 mm.

- The outside diameter of a 2-inch PVC pipe is about 60.3 mm.

- This means that in global projects, you need to know how to change the sizes of PVC pipes into mm to avoid fittings that don’t fit

Why is it hard to understand the sizes of PVC pipes?

You would think that the size of PVC pipes is measured the same way as any other round object, by its outer diameter. The nominal size method is based on old standards for steel pipes, when “size” meant the inner diameter at a certain wall thickness.

So, the same sizing rule for PVC means that the nominal size doesn’t always match the real inner or outer diameters. This makes it even harder to choose fittings or replace pipes.

Always check a chart of PVC pipe sizes and measure the outside diameter before you buy.

Applications of Different PVC Pipe Sizes

Selecting the right PVC pipe width ensures your system operates efficiently without leaks or bursts.

Residential Plumbing

- 1/2 to 1 inch: Supply lines carrying water to faucets and toilets.

- 1 1/2 to 2 inch: Drains for sinks, showers, and tubs. A 2in PVC union or 40mm waste pipe fittings (common in metric regions) are staples here.

- 3 to 4 inch: Toilet drains and main waste lines. 4in PVC cap and 4in PVC elbow fittings are common repair parts.

Commercial Plumbing

Commercial buildings handle higher volumes of waste. You will often see 6in PVC or even larger used for main trunk lines to prevent clogs.

Irrigation Systems

- 3/4 to 1 inch: Typical sprinkler lateral lines.

- 1 1/4 to 2 inch: Main supply lines for large lawns.

Industrial Applications

Factories use schedule 80 PVC water pipe and schedule 80 conduit because machinery and heavy traffic pose a risk to thinner pipes. Large dia PVC pipe (10-inch plus) is often used for fluid transfer in processing plants.

When picking the right size of PVC pipe, you should think

As a professional plumber, I saw that even homeowners made costly mistakes due to their unprofessional selecting of PVC pipes. The selection of well-chosen pipes determines the durability, safety, and efficiency of plumbing which otherwise would have also been applied in irrigation or construction. Below are the really most common mistakes that will cause one to choose the wrong pipe.

1. Flow Rate and Pressure

A smallest PVC pipe (like 1/2 inch) restricts flow significantly over long distances. If you need high volume, step up the size. Always check the PSI rating. Remember, Schedule 80 handles more pressure than Schedule 40.

2. Chemical Compatibility

Standard PVC is great for water and many acids, but it can react with certain solvents. Ensure your PVC pipe work sizes and materials match the fluid you are transporting.

3. Not Considering Temperature Limits

However, PVC is quite durable and can withstand considerable pressure through internal and external forces, but it shows some temperature limitation. Regular PVC pipe may weaken or warp when subjected to hot water and outdoor heat. If your system contains warm water or is in the sunlight, CPVC or specially UV-resistant PVC should be considered.

4. Cost

Schedule 40 PVC is significantly cheaper than Schedule 80. A 6 inch PVC pipe 20 ft price will be much higher for Schedule 80 than for sch 35 PVC pipe (a thinner drainage pipe).

5. Overlooking Chemical Compatibility

Is it fair to say that PVC is largely used in industries and not all chemicals are compatible with PVC? At such low levels of chemical resistance, PVC should not be used for strong acids, solvents, or very high concentrations of chemicals since these could oxidise the compound. Always consult a PVC chemical compatibility chart before installation.

6. Ignoring Joint and Fitting Compatibility

A joint is only as strong as the pipe itself. Improper PVC fittings can lead to leakage or weak joints. Ensure that your fittings correctly match the pipe type and size to avoid problems during installation.

7. Skipping UV Protection for Outdoor Use

Standard PVC can no longer withstand exposure to sunlight for extended periods. One common mistake is the installation of unprotected PVC outdoors, which would result in limited service life. Instead, paint the pipe with UV-resistant paint or use UV-stabilised PVC.

8. Not Consulting Local Plumbing Codes

Every region has its own plumbing code and standards. Using an incorrect pipe type can cause system failure as well as bring legal ramifications or rejected inspections, so make sure to always check your local building codes before purchasing.

Final Thoughts

Whether you are running a simple drain using 40mm waste pipe and fittings or designing a complex industrial system with schedule 80 pipe, knowing your numbers is key.

Remember:

Read the Print: The markings on the side of the pipe tell you everything from the PVC pipe size dimensions to the pressure rating.

Check the OD and ID: Know the difference between PVC pipe sizes in mm and inches.

Pick the Right Schedule: Use Sch 40 for general home use and Sch 80 for high pressure.

By choosing the correct standard PVC pipe sizes and following proper installation methods, you ensure a leak-free, durable system that will last for decades.

Frequently Asked Questions – (FAQ’s)

Conclusion

Understanding PVC pipe sizes is key to building efficient and leak-free piping systems. From small residential lines to large industrial networks, the correct size determines flow capacity, pressure tolerance, and long-term durability.

Always refer to ASTM standards, use accurate measurement tools, and consult size charts before purchasing or installing PVC pipes. Whether you’re using Schedule 40 for lightweight applications or Schedule 80 for heavy-duty systems, correct sizing ensures safety, reliability, and performance for years to come.

-

PVC Pipe Bend

Custom angles and curves are often required for pipes, wiring, or even creative DIY projects with PVC tubing. However, bending PVC incorrectly without the proper tools will result in kinks, cracks, or worse. And here’s where a PVC pipe bender comes in-to make those smooth, even bends without shredding the pipe. The guide will give…

-

PVC Nipple Sizes

Success is achieved in the smallest details in the highly complex network of pipes and fittings making plumbing systems. While large pipes deliver flow, it is the connectors that ensure the integrity of the entire system. One of the essential components among them is the PVC nipple, which serves to connect fittings and extend pipe…

-

PVC Tee

The PVC tee functions as the vital connection point which enables modern piping systems to establish their multiple pathways for liquid flow. The T-shaped connector permits precise control of fluid distribution because it enables dual path branching from a single stream and central flow merging from multiple sources. The PVC tee enables engineers to create…