PVC Pipe Fittings

Understanding Pipe Fittings PVC and Their Importance

PVC plaster board ribbons into some corner attachment parts of modern aspects of plumbing systems and piping systems. Without it, pipes can’t be joined for purposes of directing flow in precision and reliability. The versatility of these components has changed the way we think about water distribution, drainage, and even industrial fluid management. Today, there seems to be no single space where the components are not used. To know the different types of PVC Pipe Fittings, as they are being offered today, gives contractors, engineers, and DIY enthusiasts the empowerment to make better choices in their projects-from home plumbing to elaborate industrial assembly systems, whether it is a case where the fitting may be all that separates it from a system that will last for decades and one that will be destined to fail prematurely.

This full guide covers all the different types of PVC fittings, what they do, and how they can help your pipes work better. This will help you pick the best parts for long-lasting performance, whether you’re making something new or fixing something you already own.

Everything in this full-length guide covers a specific PVC fitting type, its application, and the benefits that each one contributes to your piping system. No matter whether you are building a new installation or replacing existing infrastructure, this guide will be of great importance when selecting the best options for reliable performance.

Understanding PVC Pipe Fittings and Their Importance

Indeed, the fitting of polyvinyl chloride is one of the most advanced and emerging technologies in piping. Molded components so created act as an anchor to hold together parts of a line but, in turn, tend to allow flow through a section or individual member under the extremes of pressure and temperature. They are the only economically viable possibilities for a lot of applications around the world, because they compete.

PVC fittings are precisely molded during production by the very best possible techniques, maintaining the dimensions of the fittings and the performance. They should be passed through qualifying tests to ensure their compliance with the industry requirements toward pressure ratings, compatibility with various chemicals and long-term durability. This attention to detail is the reason why PVC systems that are properly installed can go on working without needing any repairs for 50 long years or more.

The design of these fittings has changed into modern high-tech design features, which make installation fairly easier and function better. Fit in sockets then makes a tight seal; here are special gaskets and sealing systems that prevent leakage under the most adverse conditions. This provides a piping system that works optimally with little maintenance. We have also added PVC Fittings Chart which will help you choose the right size.

PVC Fittings Chart

| Fitting Name | Function / Description | Connection Type | Typical Sizes |

| Elbow 90° | Changes pipe direction by 90 degrees; used in corners or turns. | Slip, Threaded | 1/2″ – 6″ |

| Street Elbow | Has one male and one female end; connects directly to another fitting. | Male/Female Threaded | 1/2″ – 4″ |

| Tee | Joins three pipes at 90°, forming a “T” shape. | Slip, Threaded | 1/2″ – 6″ |

| Reducing Tee | Connects three pipes of different diameters. | Slip, Threaded | 1/2″ × 3/4″ – 6″ × 4″ |

| Cross (4-Way) | Connects four pipes at 90° angles; used in complex layouts. | Slip, Threaded | 1/2″ – 4″ |

| Coupling | Joins two straight pipe sections. | Slip, Threaded | 1/2″ – 8″ |

| Reducing Coupling | Connects two pipes of different diameters in a straight run. | Slip, Threaded | 1/2″ × 3/8″ – 8″ × 6″ |

| Repair Coupling | Moves telescopically to repair or replace pipe sections without cutting full length. | Telescopic Slip | 1/2″ – 4″ |

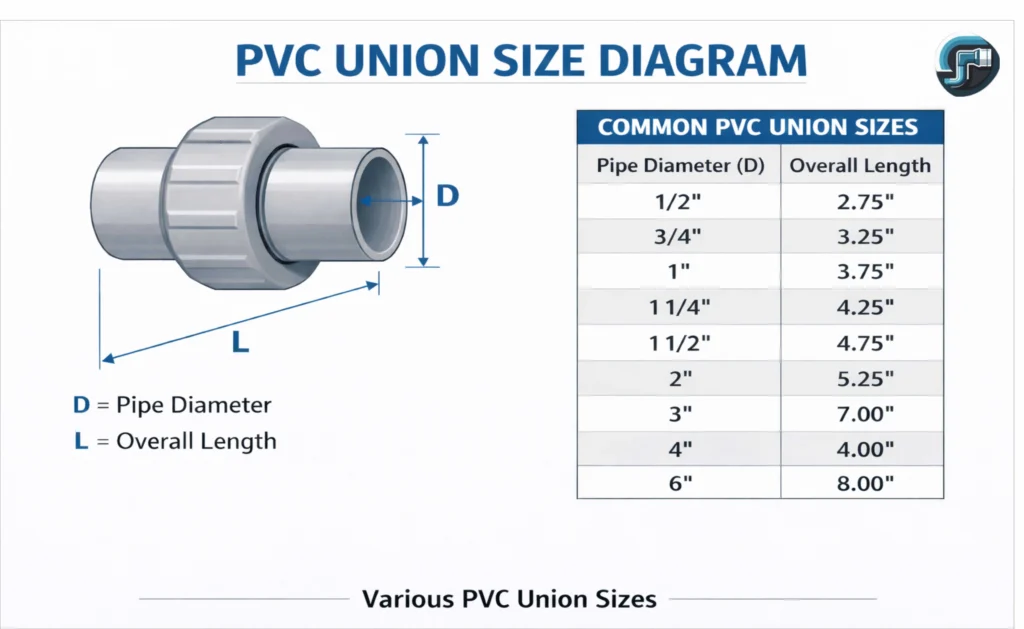

| Union | Allows quick disconnection of pipes for maintenance or replacement. | Slip, Threaded | 1/2″ – 4″ |

| Male Adapter | Converts pipe end to a male threaded connection. | Slip × Male Threaded | 1/2″ – 4″ |

| Female Adapter | Converts pipe end to a female threaded connection. | Slip × Female Threaded | 1/2″ – 4″ |

| Cap | Seals the end of a pipe permanently. | Slip, Threaded | 1/2″ – 6″ |

| Plug | Closes the end of a threaded fitting or opening. | Male Threaded | 1/2″ – 4″ |

| Bushing | Reduces fitting or pipe size within another fitting. | Slip, Threaded | 1/2″ × 3/8″ – 6″ × 4″ |

| Wye | Connects three pipes at a 45° angle for smoother flow. | Slip, Threaded | 1/2″ – 6″ |

| Double Wye | Connects four pipes in a Y-shaped configuration; often used in drainage systems. | Slip | 1-1/2″ – 6″ |

| Saddle | Creates a branch outlet on an existing pipe without cutting it completely. | Clamp-On, Threaded | 1/2″ – 4″ |

| Compression Coupling | Joins pipes without glue using rubber rings and compression nuts. | Compression Type | 1/2″ – 4″ |

| Expansion Coupling | Allows for thermal expansion and contraction of PVC pipes. | Telescopic Type | 3/4″ – 4″ |

| Ball Valve | Controls flow on/off with a rotating ball inside. | Slip, Threaded | 1/2″ – 4″ |

| Union Ball Valve | Ball valve with union ends for easy removal. | Slip, Threaded | 1/2″ – 4″ |

| Check Valve | Prevents backflow; allows flow in only one direction. | Slip, Threaded | 1/2″ – 4″ |

| Swing Check Valve | Uses a hinged flap to prevent reverse flow. | Slip, Threaded | 1/2″ – 4″ |

| Spring Check Valve | Uses a spring-loaded mechanism for quick closure. | Slip, Threaded | 1/2″ – 4″ |

| End Cap (Vent Cap) | Covers open pipe ends, often with holes for ventilation. | Slip, Threaded | 1/2″ – 4″ |

| Flange | Used for connecting PVC pipes to metal or other flanged systems. | Slip, Threaded, Bolt-On | 1/2″ – 12″ |

| Trap | Used in drainage systems to prevent sewer gas backflow. | Solvent Weld | 1-1/4″ – 4″ |

| Adapter | Converts from one fitting or pipe size/type to another. | Slip, Threaded | 1/2″ – 4″ |

| Nipple | Short length of threaded pipe used to connect two female fittings. | Threaded | 1/2″ – 4″ |

| Bulkhead Fitting | Provides a watertight seal through a tank or wall. | Threaded, Gasketed | 1/2″ – 4″ |

Essential PVC Fittings Types for Every Application

PVC Elbow: Changing Direction with Precision

PVC elbows are among the most used fittings in any piping system. These curved fittings change the direction of pipe flow through specific angles, which are most commonly 45 or 90 degrees, while still keeping the smooth flow characteristics of hydraulic systems. The smooth internal radius profile minimizes turbulence and consequently pressure losses to ensure that the system functions at maximum efficiency.

Street elbows have one socket and one spigot end, so that they can connect directly to a fitting without an intervening pipe section. PVC Elbow is especially useful in tight quarters where every inch counts. Standard elbows have socket connections on both ends, providing maximum flexibility for complex routing solutions.

Long-radius elbows provide gentler curves which further maintain flow reduction. These distinct fittings are invaluable for situations where pressure drop should be minimized, e.g., for pump-discharge piping or high-velocity applications. Reduced energy consumption and extended system life occur due to the benefit of smoother flow.

PVC Cap: Secure End Closure Solutions

A pvc cap provides reliable termination for pipe ends in both temporary and permanent applications. These simple yet essential fittings create watertight seals that withstand system pressure while protecting against contamination. Their versatility makes them indispensable for system testing, future expansion provisions, and permanent closures.

Slip caps slide over pipe ends and secure with solvent cement, creating permanent joints ideal for dead-end branches or abandoned lines. Threaded caps screw onto male pipe threads, offering removable access points for maintenance or future modifications. This flexibility proves valuable in evolving systems where access requirements may change.

Test caps serve specialized purposes during system commissioning and testing phases. These temporary closures withstand full system pressure during leak testing while allowing easy removal once testing is complete. Proper cap selection ensures reliable testing procedures and long-term system integrity.

PVC Tee: Three-Way Connection Excellence

The pvc tee creates branch connections that split flow into multiple directions while maintaining hydraulic efficiency. These fundamental fittings enable complex distribution networks that serve multiple outlets from single supply lines. Their robust construction handles the stress concentrations that occur at branch connections.

Standard tees feature equal-diameter openings that accommodate identical pipe sizes throughout the fitting. Reducing tees incorporate different sizes to transition between pipe diameters while creating branch connections. This versatility eliminates the need for separate reducers, simplifying installations and reducing potential leak points.

Sanitary tees incorporate specialized internal geometry that promotes smooth flow transitions. These fittings minimize turbulence and dead zones where debris might accumulate, making them ideal for applications requiring high hygiene standards or consistent flow characteristics.

PVC Coupling: Straight-Line Connection Solutions

A PVC Coupling joins two pipe sections in straight runs while accommodating minor alignment variations. These essential fittings repair damaged sections, extend existing lines, or connect pipes during installation. Their simple design maximises reliability while minimising installation complexity.

Slip couplings feature smooth internal bores that create continuous flow paths without restrictions. Both pipe ends insert into the coupling with solvent cement creating permanent, leak-proof joints. This configuration works well for permanent installations where future disassembly is unlikely.

Compression couplings utilise rubber gaskets and mechanical fasteners to create removable joints. These specialised fittings accommodate thermal expansion, ground settlement, or situations requiring future access. The ability to disassemble these connections makes them valuable for maintenance-intensive applications.

PVC Cross Tee: Four-Way Distribution Hub

The PVC Cross tee provides four-way pipe connections that create complex distribution networks from single supply points. These specialized fittings handle the significant stress concentrations that occur when multiple pipe runs intersect. Their reinforced construction ensures long-term reliability under varying load conditions.

Equal crosses accommodate identical pipe sizes in all four directions, creating symmetrical distribution systems. Reducing crosses incorporate different diameters to transition between pipe sizes while maintaining four-way connectivity. This flexibility enables complex networks without requiring additional transition fittings.

Installation of cross tees requires careful attention to support requirements due to the multiple pipe connections. Proper bracing prevents stress concentration that could lead to joint failure or system damage. When installed correctly, these fittings provide decades of reliable service in demanding applications.

PVC Bushing: Size Transition Solutions

A PVC Bushing reduces pipe diameter within fittings or equipment connections, enabling smooth transitions between different pipe sizes. These compact components eliminate the need for separate reducer fittings while maintaining optimal flow characteristics. Their versatility makes them essential for connecting equipment with different connection sizes.

Flush bushings create smooth internal transitions that minimize flow disruption. The gradual diameter change reduces turbulence and pressure loss compared to abrupt size changes. This careful attention to hydraulic design improves system efficiency while reducing wear on system components.

Hex bushings incorporate external hex surfaces that simplify installation and removal using standard tools. This feature proves particularly valuable in maintenance applications where fittings may require periodic replacement or adjustment. The secure grip provided by hex surfaces prevents damage during installation.

PVC Nipple: Short Connection Links

The PVC Nipple creates short connections between fittings or transitions through walls and barriers. These threaded components provide secure joints while occupying minimal space. Their compact design makes them ideal for tight installations where standard pipe lengths prove impractical.

Close nipples feature threads that nearly meet in the center, creating the shortest possible connection. Shoulder nipples incorporate a smooth center section that provides additional strength and prevents thread damage during installation. Long nipples offer extended reach for connections across thick walls or equipment housings.

Proper thread engagement ensures reliable connections that withstand system pressure and thermal cycling. Quality nipples feature precision-cut threads that create tight seals with minimal thread compound. This attention to manufacturing detail prevents leaks while simplifying installation procedures.

PVC Union: Removable Connection Technology

A PVC Union creates removable connections that enable system maintenance without cutting pipes or fittings. These specialized components incorporate threaded joints and sealing rings that provide reliable service while allowing future disassembly. Their versatility makes them essential for equipment connections and maintenance access points.

Ground joint unions feature precision-machined sealing surfaces that create reliable seals without requiring additional gaskets. The metal-to-metal contact provides consistent sealing performance across wide temperature ranges. Regular maintenance of these sealing surfaces ensures continued leak-free operation.

O-ring unions utilize elastomeric seals to create watertight joints that accommodate minor misalignment and thermal movement. The flexible sealing system adapts to varying conditions while maintaining consistent performance. Proper O-ring selection ensures chemical compatibility and long service life.

PVC Adapter: Interface Solutions

The PVC Adapter connects PVC components to other piping materials or equipment with different connection types. These versatile fittings bridge the gap between dissimilar systems while maintaining leak-proof connections. Their broad range of configurations accommodates virtually any connection requirement.

Male adapters feature external threads that connect to female-threaded components. Female adapters incorporate internal threads for connection to male-threaded equipment. Slip adapters combine socket connections with threaded ends, providing maximum installation flexibility.

Flanged adapters enable connections to flanged equipment or valve systems. The bolt patterns match standard flange specifications while providing reliable sealing performance. These adapters eliminate the need for specialized flanged pipe sections, reducing inventory requirements and installation complexity.

PVC Flange: Heavy-Duty Connection Systems

A PVC Flange creates robust connections for valves, equipment, and high-pressure applications requiring secure, removable joints. These components distribute connection loads across large areas, reducing stress concentrations that could cause joint failure. Their standardised dimensions ensure compatibility with equipment from various manufacturers.

Van Stone flanges incorporate loose backup rings that accommodate thermal expansion while maintaining tight seals. The flexible design prevents stress concentration during temperature cycling, extending system life in demanding applications. Proper gasket selection ensures chemical compatibility and sealing performance.

Threaded flanges combine the convenience of threaded connections with the strength of bolted joints. These hybrid components simplify installation while providing the security required for critical applications. The combination of connection methods creates redundant sealing that enhances system reliability.

PVC Plug: Temporary and Permanent Closures

The PVC Plug provides secure closure for openings in fittings, equipment, or pipe systems. These simple components create watertight seals while occupying minimal space. Their availability in various configurations accommodates different closure requirements and access needs.

Threaded plugs screw into female-threaded openings, creating removable closures for maintenance access or testing ports. Square head plugs incorporate raised surfaces that accept standard tools, simplifying installation and removal procedures. Hex head plugs provide secure grip while minimizing the space required for tool access.

Expansion plugs utilize mechanical action to create tight seals in smooth-bore openings. These specialized closures accommodate applications where threaded connections are impractical or unavailable. The self-sealing action creates reliable closures without requiring thread compounds or gaskets.

PVC Wye: Efficient Branch Connections

A PVC wye creates branch connections at 45-degree angles that optimize flow characteristics while reducing pressure loss. These specialized fittings prove particularly valuable in drainage applications where smooth flow transitions prevent blockages and improve system performance. The gentle angle change minimizes turbulence compared to standard tee fittings.

Sanitary wyes incorporate internal geometry specifically designed for waste and drainage systems. The smooth transitions prevent solids accumulation while promoting self-cleaning action. These features make them essential components in gravity-fed drainage networks where flow consistency is critical.

True wyes maintain equal diameters throughout all openings, creating symmetrical flow patterns. Reducing wyes incorporate different sizes to accommodate transitions between pipe diameters while maintaining optimal flow characteristics. This versatility enables complex drainage networks without compromising performance.

PVC Valves: Flow Control Solutions

PVC valves provide essential flow control functions while maintaining chemical compatibility with PVC piping systems. These components regulate flow, pressure, and direction while withstanding the corrosive conditions that would damage metal alternatives. Their lightweight construction simplifies installation and maintenance procedures.

Ball valves offer reliable shutoff service with quarter-turn operation that minimizes operator effort. The spherical closure element creates tight seals while providing unrestricted flow in the open position. Lever handles provide clear position indication and easy operation even with gloved hands.

Check valves prevent reverse flow that could damage equipment or contaminate supply sources. Spring-loaded designs ensure positive closure while minimizing pressure loss during normal operation. The chemical resistance of PVC components ensures reliable operation in demanding environments.

PVC Trap: Drainage Protection Systems

The PVC Trap prevents sewer gases from entering buildings while allowing waste water to flow freely. These essential components create water seals that block harmful gases while accommodating the flow surges typical in drainage systems. Their smooth internal surfaces resist buildup that could impede drainage or create odors.

P-traps incorporate the familiar curved configuration that creates reliable water seals. The deep seal prevents gas penetration even during extended periods without flow. Cleanout plugs provide access for clearing blockages without removing the entire trap assembly.

S-traps utilize multiple direction changes to create effective seals while accommodating space constraints. These specialized configurations prove valuable where standard P-trap installations are impractical. Proper venting prevents siphoning that could break the water seal and allow gas penetration.

Selection Criteria and Best Practices

Choosing the appropriate PVC fittings requires careful consideration of application requirements, environmental conditions, and long-term performance expectations. Pressure ratings must exceed maximum system pressures with appropriate safety factors. Temperature considerations include both operating ranges and thermal cycling effects.

Chemical compatibility extends beyond the conveyed fluid to include cleaning agents, atmospheric conditions, and potential contamination sources. UV exposure requires stabilized formulations or protective coatings to prevent degradation. Soil conditions affect buried installations where chemical attack or physical damage could occur.

Installation procedures significantly impact long-term performance regardless of fitting quality. Proper joint preparation, cement application, and curing procedures ensure reliable connections that withstand service conditions. Regular inspection and maintenance preserve system integrity while identifying potential issues before failure occurs.

Conclusion

PVC fittings are a tried-and-true technology that is always changing to meet the needs of the industry. They are the best choice for many things around the world because they are reliable, work well, and are cheap. You can design and install a system correctly if you know the different types of fittings, what makes each one unique, and how to use them properly.

Modern PVC fittings can be used for a wide range of things, from simple home plumbing to complicated industrial process systems. These have more benefits than just the initial cost. They don’t break down in chemicals, keep their shape, and are easy to put together. It will last for decades with little upkeep if you pick the right one and put it in the right way.

You need to make sure that the parts of your PVC fitting system can do their jobs and that you follow tried-and-true installation methods to make them work. PVC technology is an important part of building and improving infrastructure today because it has a lot of different fittings that can be used to fix almost any problem with pipes.