PVC Coupling

The PVC pipe is just about the simplest building block that the plumbing and construction industry has to offer. It’s perfect for everyone’s budget, and it can stand quite a lot on its own with dignity. But, you see, a pipe is only as good as the way it connects. That’s where the all-important PVC coupling comes in handy-a pretty handy fitting for forming reliable leak-proof pipe systems for all those out there-whether you’re a plumbing contractor, building manager, or self-styled project DIYer-it is wise to learn about what makes that particular coupling tick, as it can have such a significant impact on a project.

So, this is the guide to PVC couplings-everything from the basic uses to the different types of PVC couplings, and the various sizes and applications in between. By the end, you should know basically how to choose and work with the right coupling for the job to ensure your PVC pipe networks will hold up over time.

What is a PVC Coupling?

A PVC coupling is a fitting that connects two pieces of PVC pipe in a straight line. The main job of this tool is to fix a broken pipe or add length to a pipe run. These fittings are simple in design but very important for the safety of any plumbing, irrigation, or drainage system. Couplings are made from the same polyvinyl chloride material as the pipes they connect. This makes sure that the connection is strong and long-lasting and won’t corrode, break down, or wear out over time.

Solvent cement is a chemical welding process that joins the PVC coupling pipe fitting to the pipe itself. This makes a seal that is permanent, waterproof, and can handle a lot of pressure. Because it is simple and works well, the PVC coupling is a popular choice for many uses.

PVC Coupling Sizes Chart

| Nominal Pipe Size (inches) | Outside Diameter (OD) | Inside Diameter (ID) | Coupling Length |

| 1/2″ | 0.84″ (21.34 mm) | 0.622″ (15.8 mm) | 1.50″ – 2.00″ |

| 3/4″ | 1.05″ (26.67 mm) | 0.824″ (20.9 mm) | 1.50″ – 2.25″ |

| 1″ | 1.315″ (33.40 mm) | 1.049″ (26.6 mm) | 2.00″ – 2.50″ |

| 1 1/4″ | 1.660″ (42.16 mm) | 1.380″ (35.0 mm) | 2.25″ – 3.00″ |

| 1 1/2″ | 1.900″ (48.26 mm) | 1.610″ (40.9 mm) | 2.50″ – 3.00″ |

| 2″ | 2.375″ (60.33 mm) | 2.067″ (52.5 mm) | 3.00″ – 3.50″ |

| 2 1/2″ | 2.875″ (73.03 mm) | 2.469″ (62.7 mm) | 3.50″ – 4.00″ |

| 3″ | 3.500″ (88.90 mm) | 3.068″ (77.9 mm) | 4.00″ – 4.50″ |

| 4″ | 4.500″ (114.30 mm) | 4.026″ (102.3 mm) | 4.50″ – 5.50″ |

| 5″ | 5.563″ (141.30 mm) | 5.047″ (128.2 mm) | 5.50″ – 6.00″ |

| 6″ | 6.625″ (168.28 mm) | 6.065″ (154.0 mm) | 6.00″ – 7.00″ |

| 8″ | 8.625″ (219.08 mm) | 7.981″ (202.7 mm) | 7.00″ – 9.00″ |

| 10″ | 10.750″ (273.05 mm) | 10.020″ (254.5 mm) | 8.00″ – 10.00″ |

| 12″ | 12.750″ (323.85 mm) | 11.938″ (303.2 mm) | 10.00″ – 12.00″ |

Common Uses for PVC Couplings

There are generally PVC couplings in either the residential, commercial, or industrial properties. Their usefulness results in an application in almost every system.

Plumbing: PVC couplings are used in household plumbing attached to its drain, waste, and vent (DWV) systems. It runs for lengths of pipes to link up around sinks, toilets, and showers to get wastewater discharged.

Irrigation: The coupling serves during landscaping and agriculture to set up long lines of irrigation supplying water to lawns, gardens, and crops as a customized design and repair without major contract implication.

Drainage: The use of couplings is mostly applicable in the construction of storm drainage systems, which remove rainwater runoff from buildings, roads, and properties so that flooding can be avoided.

DIY Projects: PVC pipes, in addition to the standard uses, can be used quite inexpensively and easily to assemble into furniture and storage racks and any other creative structures.

Pipe Repair: A coupling, commonly a PVC slip coupling, will cut out the bad section of a pipe and join in a new piece seamlessly whenever an area of pipe breaks.

Understanding the Main PVC Coupler Types

Not all couplings are created equal. Different situations call for different designs. Understanding the primary pvc coupler types is key to choosing the correct fitting for your specific need.

Standard (Slip) Coupling

The most common type is the standard or slip coupling. It features a smooth, socket-like opening on both ends. To use it, you apply PVC primer and then solvent cement to the outside of the pipes and the inside of the coupling. The pipes are then pushed into the fitting and given a quarter turn to spread the cement evenly. This creates a strong, permanent weld.

This standard fitting is the workhorse of PVC connections. It’s used for extending pipe runs and is available in every conceivable size, from a small 1 2 PVC coupling for minor projects to a large 4 PVC coupling for main drainage lines. When you see a reference to a PVC coupling 1, PVC coupling 2, PVC coupling 3, or PVC coupling 4, it typically refers to these standard slip fittings in their respective inch measurements.

PVC Slip Coupling (Repair Coupling)

PVC slip coupling is an easy plumbing yet highly effective fitting that connects two PVC pipes in a straight line. Unlike threaded fittings, however, the ends of the pipes slide into it and then bond tightly with the aid of PVC primer and cement. It is one of the most preferred types of coupling for water supply lines, irrigation systems, and drainage applications where permanent bonding is critical.

Ease of installation is one of the main benefits of a PVC slip coupling. No threads equate to just cutting the pipe to the desired length, cleaning the ends, and applying the adhesive before inserting the pipes into the coupling. Once cured, the connection is strong, leak resistant, and durable in that it can hold pressure from water over an extended time.

PVC slip couplings are available in different sizes to match standard PVC pipe diameters, ranging from half an inch to several inches. They are lightweight, resistant to corrosion, and cost-effective, making them a popular choice for both residential and commercial plumbing projects. For situations where a quick, permanent fix is needed, a PVC slip coupling offers a reliable and efficient solution.

PVC Coupling Reducer (Bushing)

A PVC coupling reducer is an extremely versatile plumbing fitting that connects two PVC pipes with difference in diameter. It acts as a transition piece by reducing or enlarging the flow from one pipe size to another with secure, leak-proof connections between two pipes. These fittings are widely used in plumbing systems, irrigation systems, and industrial applications, indulging in maximum utility in joining pipes of different diameters.

The design of a PVC coupling reducer is pretty basic. It has two socket ends for being connected to pipes of different diameter-one larger and one smaller. The two pipes are, therefore, bonded together with PVC of a different size, by means of primer and some cement. Once installed, the transition is controlled by smooth flow through the reducer minimizing turbulence and pressure loss in the system.

One of the best advantages of PVC coupling reducers is their power. Constructed from polyvinyl-chloride, they are resistant to corrosion, rust, and chemical damage. This makes them an excellent choice for use in the water supply, drainage, and chemical-handling industries. Lightweight, easy to assemble, and with a wide range of size combinations, they offer maximum flexibility for varied piping configurations.

PVC Coupling Threaded

A PVC threaded coupling is a kind of pipe fitting that serves to link two PVC pipes with threaded ends on the same axis. In contrast, slip couplings require primer though not with cement; in the case of those fittings, these have internationally threaded ends so the given male-threaded pipes can be screwed in firmly. Thus, installation and removal are completely mechanical and swift–still without glue, proudly suggesting that they might get tried out in situations needing regular maintenance or alteration.

PVC threaded fittings have turned out themselves frequently outside supplies of drinking water, agricultural irrigation buildings, swimming pool hydraulic systems and some industrial plants. With threads, assemblies become easily to un assemble, which is particularly useful when replacing or reworking a section of pipe without cutting. They are also resistant to corrosion, rust, and nearly all chemicals, which make them arguably durable in continuous operation.

Available in several different sizes to comply with standard PVC pipe diameters, PVC couplings are lightweight and quite advantageous to handle. While the coupling is being installed, keep in mind to use thread sealant tape or paste to avoid leaks from the joints.

PVC Coupling Compression

PVC compression coupling is a sort of specialty pipe fitting designed to join two sections of PVC pipe together without threads, glue, or primer. Instead, it uses a compression system, most frequently a rubber gasket and tightening nut, to create a watertight seal over the pipe. For this reason, it is very handy in situations where pipes need to rapidly be joined, repaired, or replaced without dismantling enormous sections of the plumbing system.

Another great advantage of a PVC compression coupling is its ease in installation. You just slide in the ends of the pipe into the coupling and then tighten the compression nuts by wrench or by hand. The coupling’s gasket is compressed over the pipe to form a tight, leak-proof joint. Because no cement is used, changing or repair is a breeze if changes or repair are necessary.

PVC compression couplings are usually used in irrigation, drinking water supply lines, and in repair work. Ideal for temporary, emergency, repair work, as well as in permanent installations where flexibility is a desired choice, PVC compression couplings are lightweight, corrosion-proof, and reusable. These are a reliable, easy-to-use choice for PVC piping connection in domestic as well as commercial applications.

PVC Expansion Coupler

PVC expansion coupler, PVC expansion joint, or expansion coupling refers to a unique coupling designed for accommodating normal expansion and contraction of PVC pipework due to variations in temperatures. Since PVC shrinks and expands a great deal when hot and cold, an expansion coupler prevents stress, warping, or cracking of plumbing and conduit installations by accommodating controlled pipe movement.

The PVC expansion coupler has a telescoping sleeve that slides in and out of the fittings’ body. The sliding action offsets pipe movement, maintaining a closed link. The coupler is generally found in long, straight lines of PVC piping—hot and cold water lines, sprinkler lines, or electric conduit—where expansion from heat is most likely to occur.

Expansion coupler is one of the main pros when considering using it in a system. By reducing joint and fitting stress, it prevents leakage and breakdowns that would otherwise result from thermal variations. Installation is simple, with appropriate aligning of the coupler along the pipe run and in some cases solvent welding for a secure attachment.

Expansion couplers are lightweight, powerful, and corrosion-proof, and as such are an essential component in those installations where temperatures will vary or where exposures are exterior.

A Closer Look at Common PVC Coupling Sizes

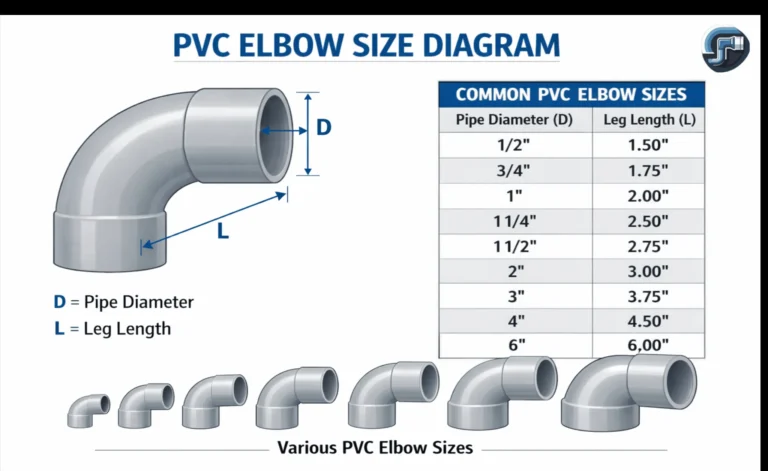

PVC couplings are categorized by the nominal pipe size they are designed to fit. It’s important to match the coupling size to the pipe’s outer diameter. Let’s look at some of the most frequently used sizes.

1 2 PVC Coupling: This small size is very common in residential DIY projects, small-scale irrigation (like drip systems), and some low-flow drainage applications. Its compact nature makes it easy to work with in tight spaces.

3 4 PVC Coupling: Slightly larger, the 3 4 PVC Coupling is a staple in residential irrigation systems for sprinkler lines and in some plumbing vent applications. It offers a good balance of flow capacity and compact size.

1 1 4 PVC Coupling: This size is often used for pool and spa plumbing, sump pump discharge lines, and larger irrigation main lines. It can handle a higher volume of water than the smaller sizes.

2 PVC Coupling: The 2 PVC Coupling is a standard for many residential drainage applications, such as connecting kitchen sinks, laundry tubs, and shower drains to the main stack. The 2 inch PVC Coupling provides excellent flow for these uses.

3 PVC Coupling: Moving into larger diameters, the 3 PVC coupling is commonly used for main drain lines in residential plumbing, connecting multiple fixtures to the sewer line. It’s the standard size for toilet drains.

4 PVC Coupling: The 4 PVC Coupling is typically used for the main building drain that connects a house’s entire plumbing system to the municipal sewer or septic system. It’s also widely used in commercial applications and for storm drainage systems due to its large capacity.

How to Properly Install a PVC Coupling?

To make sure a connection doesn’t leak and lasts a long time, it needs to be installed correctly. Even though the process is simple, skipping steps can cause the joints to fail. This is a step-by-step guide for putting together a standard solvent-weld PVC coupling.

Cutting the Pipe: Use a fine-toothed saw or a PVC cutter to make a straight, clean cut on the pipe. A square cut is very important to make sure the pipe fits snugly into the coupling socket.

Deburr the Pipe: The edges of the pipe will be rough on both the inside and outside after cutting. You can get rid of burrs with a deburring tool or a utility knife. This stops shavings from getting into the system and makes sure the surface is smooth for a snug fit.

Not wet Fit the Connection: Put the pipe and coupling together without using any primer or cement. This lets you see how well it fits and make any alignment marks you need to. The pipe should fit tightly into the socket.

Put on Primer: Put a coat of PVC primer on the outside of the pipe end and the inside of the coupling socket. Primer gets the PVC ready for the solvent cement by cleaning it and making it softer. Use a primer that is a different color than the pipe (usually purple) so you can see how well it covers.

Use solvent cement: While the primer is still wet, put a thick, even layer of PVC solvent cement over the primed areas on the pipe and the coupling.

Put the Pieces Together: Push the pipe all the way into the coupling right away, until it hits the internal stop in the socket. As you push the pipe in, turn it a quarter turn. This step helps spread the cement out evenly and get rid of air bubbles.

Hold and Cure: For about 30 seconds, hold the joint firmly in place. The solvent cement dries quickly, and holding the joint keeps the pipe from pushing back out of the fitting. Before putting pressure on the system, let the joint dry for the time that the cement maker says it should.

Frequently Asked Questions (FAQ’s)

Conclusion

The PVC Coupling is the basic building block of modern plumbing and pipe systems. Any simple to complex application, such as extending a pipe and allowing for thermal expansion, presents a design feature in a PVC Coupling. Understanding the various types of PVC Couplings-from standard slip and repair couplings to reducer, threaded, and compression models-gives you the confidence to build, repair, or maintain any of these systems.

When calling for a tiny 1 2 PVC Coupling or a more significant 4 PVC Coupling, proper selection of the fitting and proper installation are paramount. This enables both the professionals and the DIYs to build reliable, efficient, and durable PVC networks that last for years to perform perfectly.